Imagine being able to construct a fully-functional building in a day. Now, imagine being able to do ten of them in a single day. That’s the future of 3D printing in construction.

It’s hard to believe that 3D printing technology has been around for over 30 years. In that time, it has advanced rapidly and is now being used in a wide variety of industries, including construction. In this blog post, we at GLXY Software Solutions will look at the history of 3D printing in construction, its benefits and challenges, and what the future of 3D printing in this industry looks like.

The History of 3D Printing in Construction

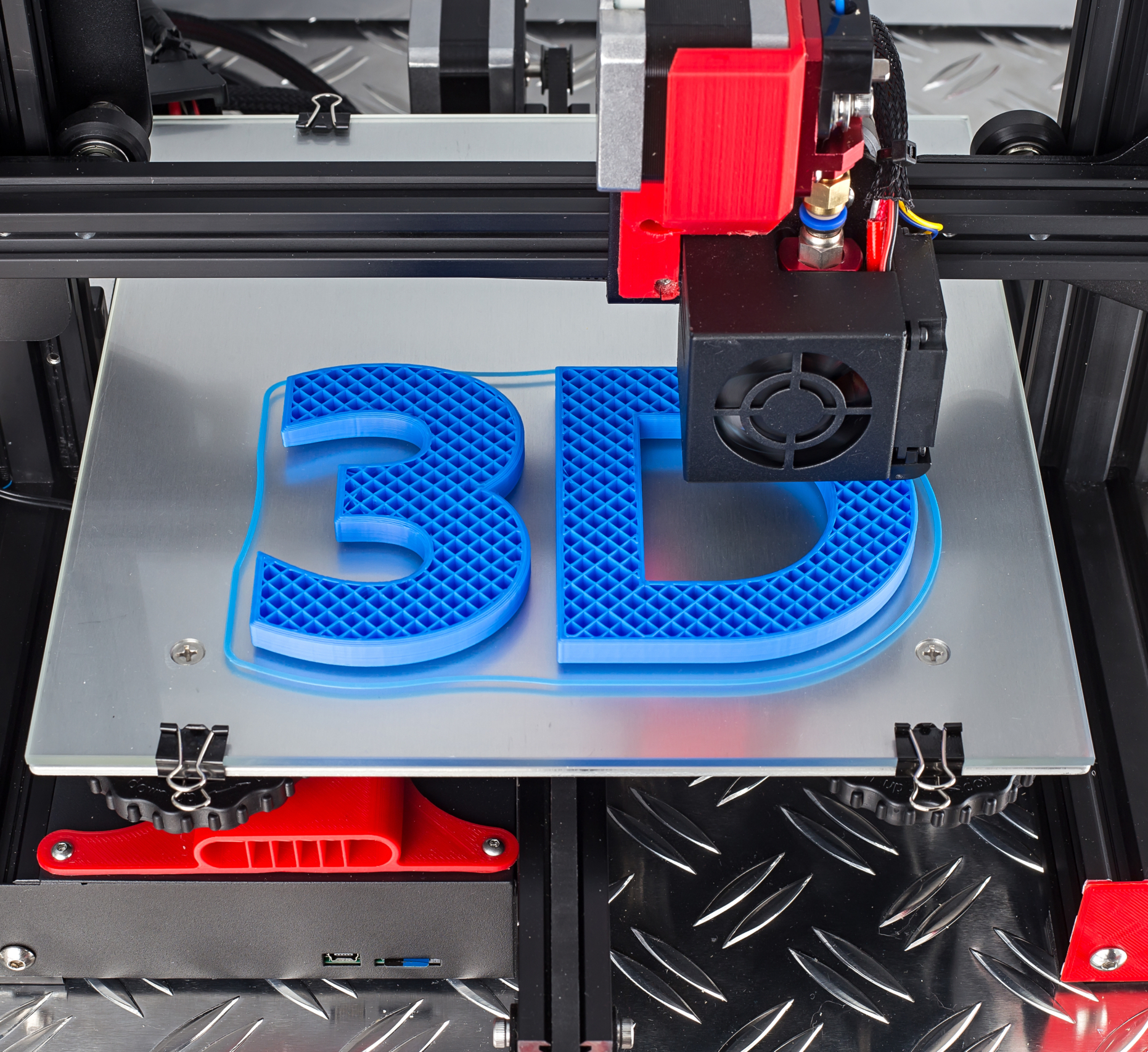

3D printing technology was first invented in the 1980s. However, it wasn’t until the early 21st century that this technology was used on a larger scale. One of the main reasons for this is that 3D printers have become much more affordable in recent years. In fact, you can now find decent-quality 3D printers for under $500. The price of filament (the material used by 3D printers to create objects) has also decreased significantly.

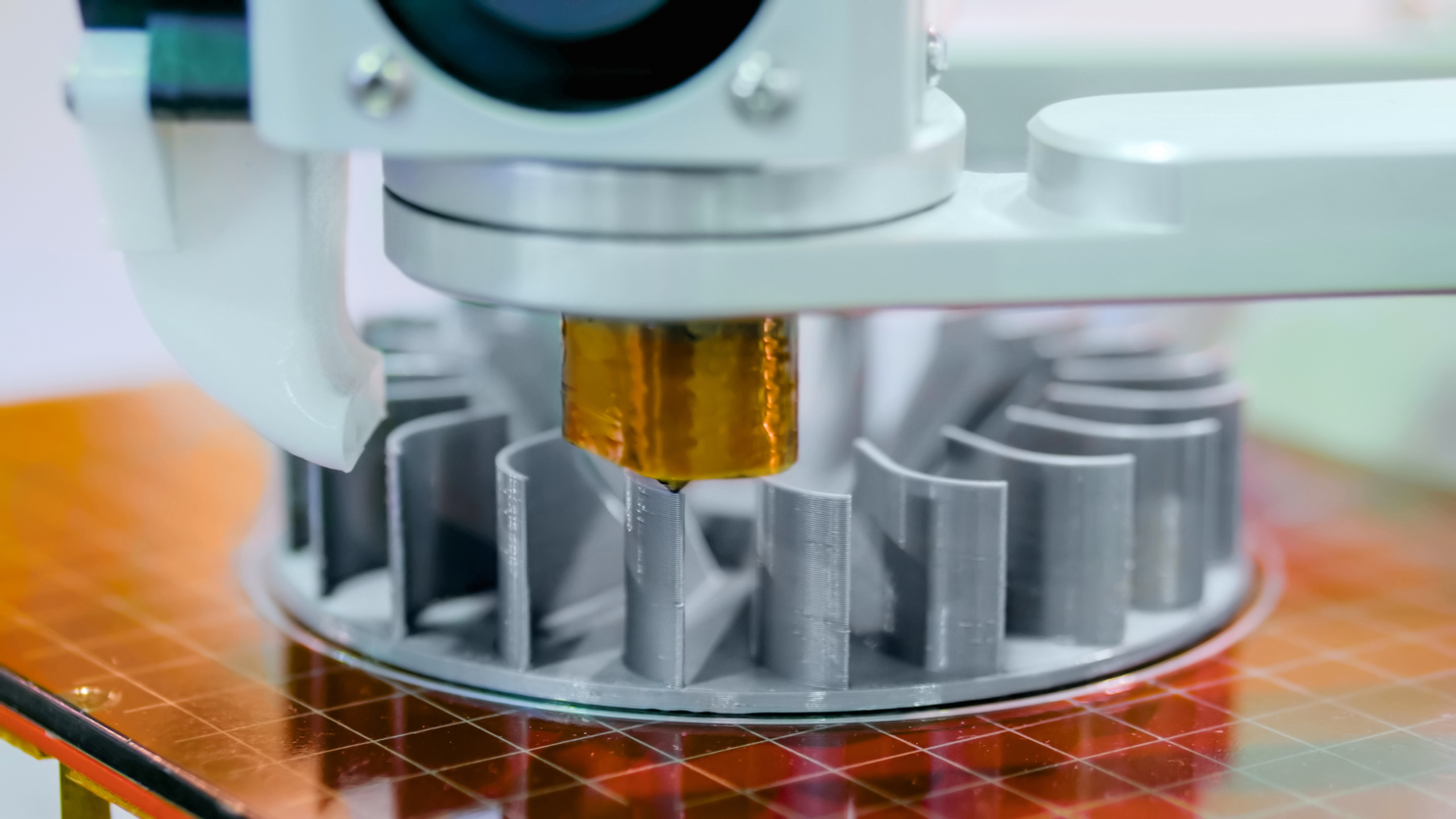

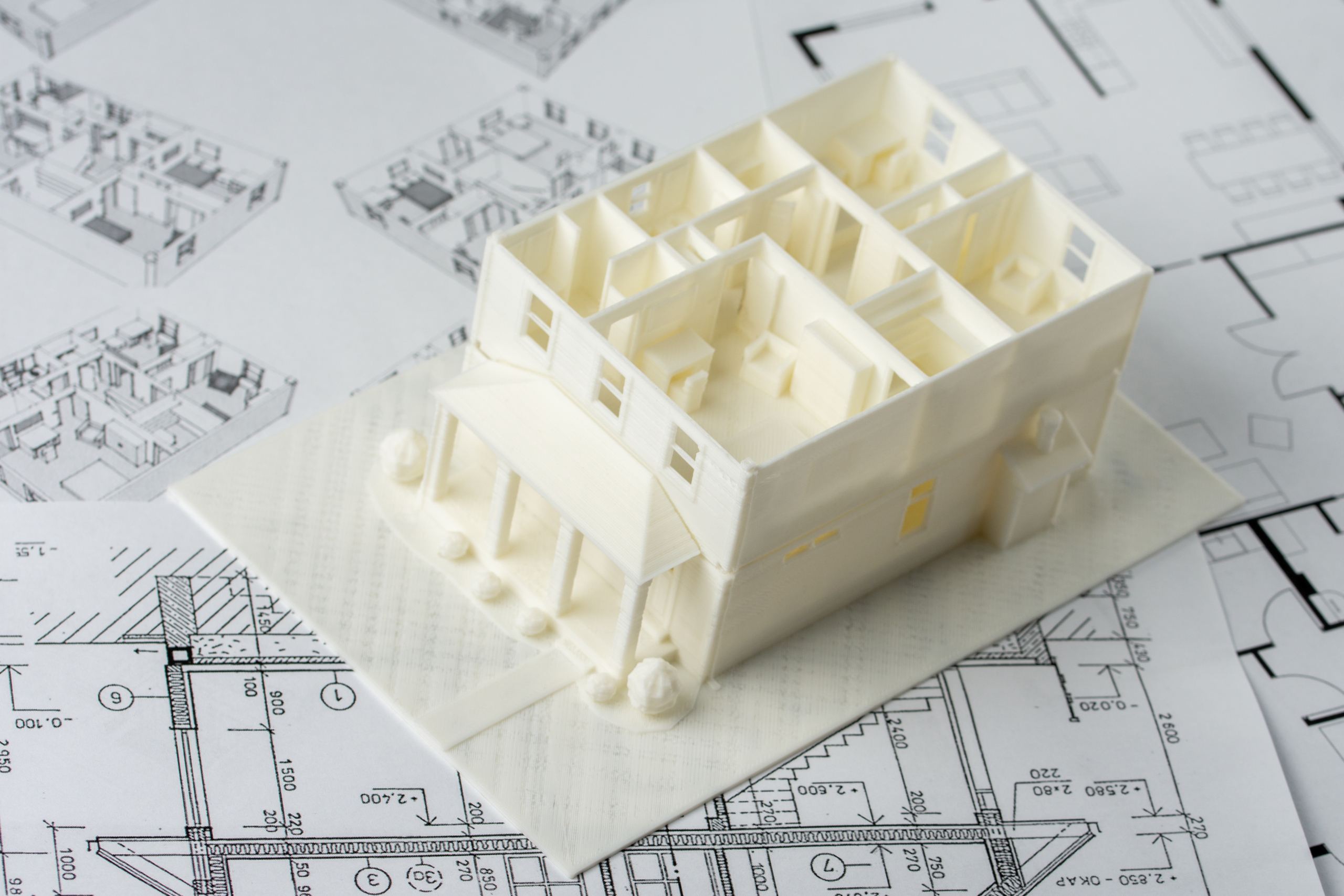

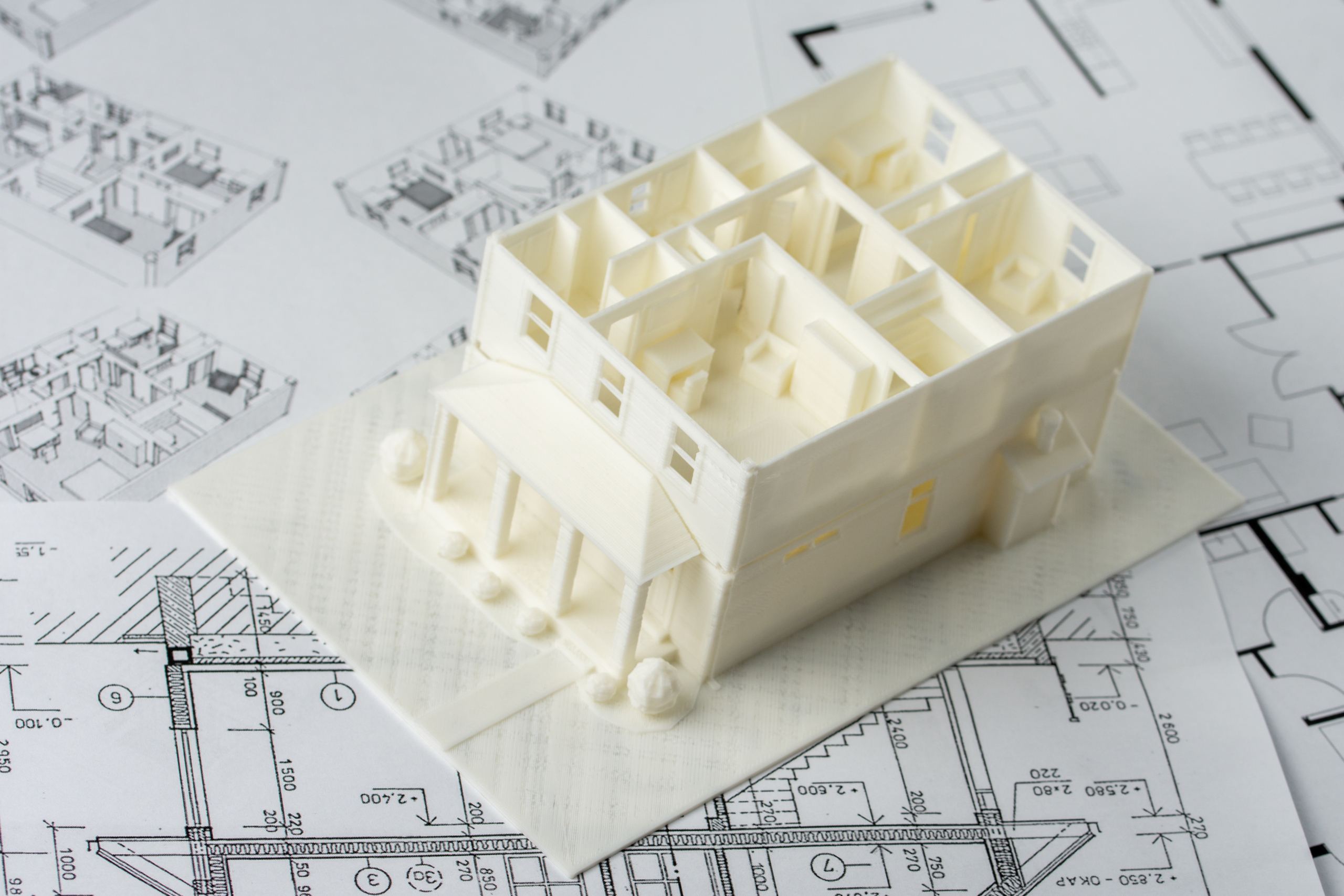

One of the earliest examples of 3D-printed construction was a concrete house built in China in 2002. In 2005, an American company called Contour Crafting Corporation successfully 3D printed a 1-to-3 scale model of a 2,500-square-foot house. And in 2014, another American company called D-Shape Enterprises printed a full-scale prototype of a mansion using a 6-meter (20-foot) tall 3D printer.

How 3D Printing Has Advanced in Recent Years

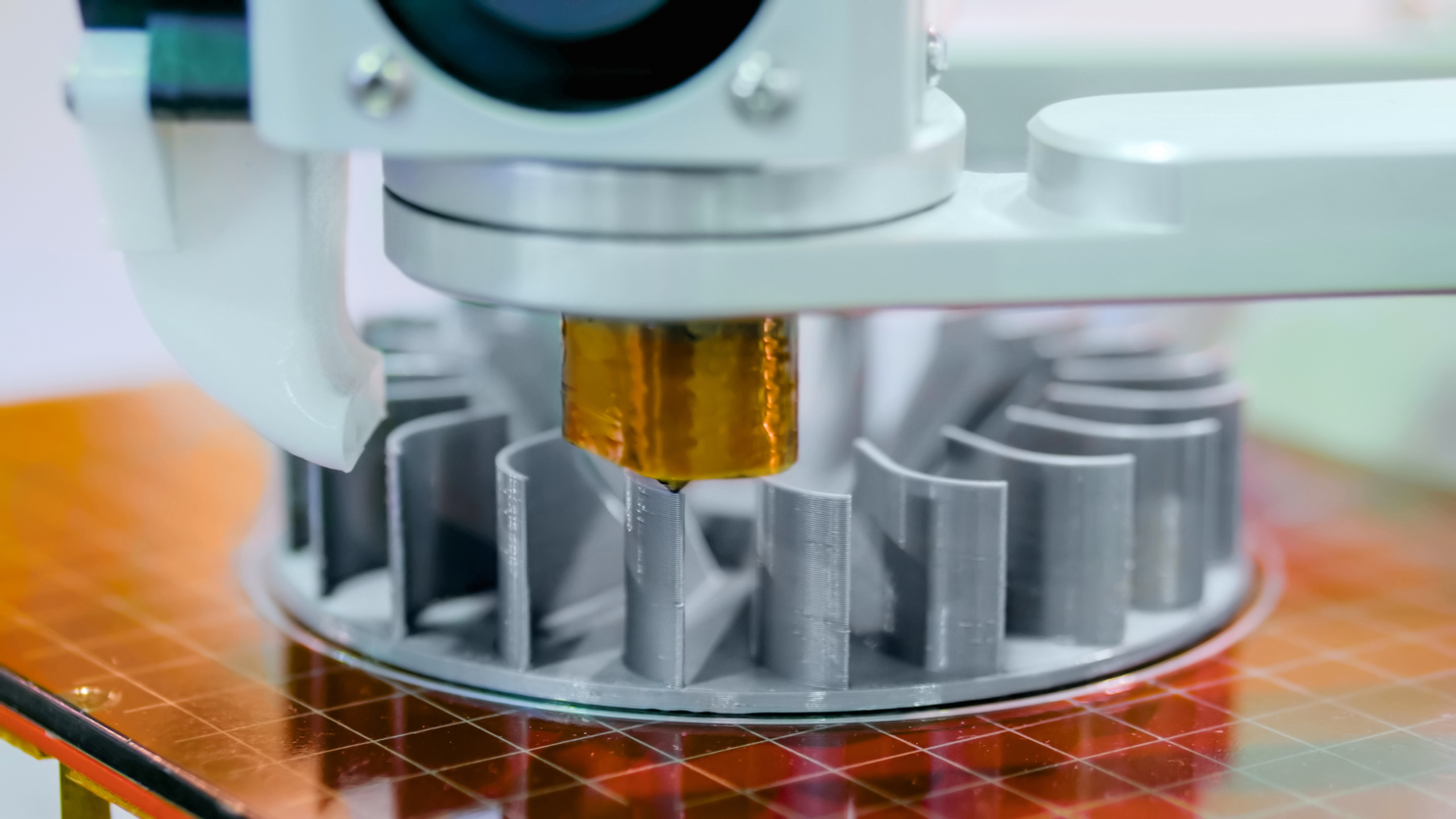

3D printing technology has gained popularity in recent years because of the advancements made in printer hardware and software. These days, there are many different types of 3D printers available on the market, each with its own strengths and weaknesses. As a result, companies or individuals can choose a printer that is best suited for their needs.

For example, some printers are desiigned for creating small objects, while others are better suited for creating large objects. Additionally, there have been significant advancements made in terms of the software used by 3D printers. This has made it easier than ever before to design and print objects.

Since the adoption of 3D printing in the early 2000s, there have been many other examples of 3D-printed homes and buildings around the world. In 2015, a company called KamerMaker built Amsterdam’s first fully permitted 3D-printed office building. In 2013, a company called Winsun built 10 houses in one day using a 20-meter (65-foot) tall 3D printer. And in 2015, Dubai announced its plans to build the world’s first fully functional 3D-printed office building.

How 3D Printing Has Advanced in Recent Years

3D printing technology has gained popularity in recent years because of the advancements made in printer hardware and software. These days, there are many different types of 3D printers available on the market, each with its own strengths and weaknesses. As a result, companies or individuals can choose a printer that is best suited for their needs.

For example, some printers are desiigned for creating small objects, while others are better suited for creating large objects. Additionally, there have been significant advancements made in terms of the software used by 3D printers. This has made it easier than ever before to design and print objects.

Since the adoption of 3D printing in the early 2000s, there have been many other examples of 3D-printed homes and buildings around the world. In 2015, a company called KamerMaker built Amsterdam’s first fully permitted 3D-printed office building. In 2013, a company called Winsun built 10 houses in one day using a 20-meter (65-foot) tall 3D printer. And in 2015, Dubai announced its plans to build the world’s first fully functional 3D-printed office building.

Benefits of 3D Printing in Construction

Benefits of 3D Printing in Construction

There are many benefits to using 3D printing technology in construction. First, it is much faster than traditional methods of construction. For example, it took KamerMaker just 72 hours to print the office building it made in The Netherlands. Second, it is much more environmentally friendly than traditional methods of construction. This is because there is very little waste generated when using a 3D printer.

Saving Time and Money

Perhaps one of the biggest benefits of using 3D printing technology in construction is that it can help save time and money. For example, if a construction company needs to create a custom part for a project, they can simply design it using computer-aided design (CAD) software and then print it out using a 3D printer.

This eliminates the need to outsource this step to another company, which can save both time and money. If a construction company needs to make multiple copies of an object (e.g., brackets), they can simply print out as many as they need. Using a 3D printer rather than having to create each one individually by hand or with traditional manufacturing methods, such as injection molding, saves time.

3D printing is simply much cheaper than traditional methods of construction. This is because you do not need to use as much material. By design, 3D printing also allows for more creativity and customization than traditional methods of construction. You are no longer limited by the size or shape of your material.

This eliminates the need to outsource this step to another company, which can save both time and money. If a construction company needs to make multiple copies of an object (e.g., brackets), they can simply print out as many as they need. Using a 3D printer rather than having to create each one individually by hand or with traditional manufacturing methods, such as injection molding, saves time.

3D printing is simply much cheaper than traditional methods of construction. This is because you do not need to use as much material. By design, 3D printing also allows for more creativity and customization than traditional methods of construction. You are no longer limited by the size or shape of your material.

3D Printing Improves Safety in Construction

Using 3D printing technology in construction can also help to improve safety on job sites. For example, if a construction company needs to create a model of a building before starting work on it, they can do so using a 3D printer. Doing so avoids putting workers at risk by not having them work on-site without any prior knowledge of what they’ll be dealing with.

If there are parts of a job site that are difficult or dangerous to reach (e.g., high up on scaffolding), workers can also use drones. These drones are equipped with 3D printers that print out objects such as tools or parts needed for repairs without putting workers in harm’s way.

3D Printing Improves Safety in Construction

Using 3D printing technology in construction can also help to improve safety on job sites. For example, if a construction company needs to create a model of a building before starting work on it, they can do so using a 3D printer. Doing so avoids putting workers at risk by not having them work on-site without any prior knowledge of what they’ll be dealing with.

If there are parts of a job site that are difficult or dangerous to reach (e.g., high up on scaffolding), workers can also use drones. These drones are equipped with 3D printers that print out objects such as tools or parts needed for repairs without putting workers in harm’s way.

Challenges of 3D Printing in Construction

Challenges of 3D Printing in Construction

Despite the many benefits of using 3D printing technology in construction, there are also some challenges that need to be addressed before it can be widely adopted. First, there is currently a lack of standards and regulations governing the use of 3D printers in construction. This needs to be addressed before companies will feel comfortable investing sizable sums of money into this new technology.

Second, most existing commercial printers are not big enough to print an entire building at once. This means that they would need to be adapted or built specifically for this purpose, something which would add high costs to projects that are already costly enough as it is.

Materials that can be used with existing printers are also limited. This means that, for now, construction companies are only really able to print small parts or prototypes rather than complete buildings. Investment from both the government and industry leaders will be required before these challenges are surmounted.

The Future of 3D Printing in Construction

Despite the challenges, the future of 3D printing in construction is looking bright. Technology is constantly developing and improving, meaning that the challenges the industry currently faces will eventually be overcome. Once this happens, there will be widespread adoption of 3D printing technology in construction, revolutionizing the way structures are built.

Examples of what can be expected include:

- The ability to print entire buildings in a matter of hours

- The use of sustainable materials such as bamboo and other plant-based materials

- The construction of homes that are specifically tailored to the needs of their occupants

3D printing will also allow building on sites that are difficult or impossible to access using traditional methods, such as on Mars or even the moon.

The possibilities are endless; it is only a matter of time before 3D printing completely changes the construction industry as it exists today.

The Future of 3D Printing in Construction

Despite the challenges, the future of 3D printing in construction is looking bright. Technology is constantly developing and improving, meaning that the challenges the industry currently faces will eventually be overcome. Once this happens, there will be widespread adoption of 3D printing technology in construction, revolutionizing the way structures are built.

Examples of what can be expected include:

- The ability to print entire buildings in a matter of hours

- The use of sustainable materials such as bamboo and other plant-based materials

- The construction of homes that are specifically tailored to the needs of their occupants

3D printing will also allow building on sites that are difficult or impossible to access using traditional methods, such as on Mars or even the moon.

The possibilities are endless; it is only a matter of time before 3D printing completely changes the construction industry as it exists today.

The Bottom Line

The Bottom Line

While there are some challenges that need to be addressed before it can be widely adopted, the future of 3D printing in construction can only continue to evolve. This new technology has the potential to revolutionize the way structures are built, making construction quicker, easier, and more sustainable.

It is clear that 3D printing technology has great potential within the construction industry, and those who are willing to invest early on will reap the rewards. In fact, you can expect to see continued progress being made with this technology. In short, 3D printing promises to revolutionize the way our homes and cities are built.

If you’d like to learn even more about the way 3D printing is advancing today, please click on the link below to get additional information.